Zinc Coated Magnets

Zinc coatings offer higher resistance to corrosion than Nickel coatings are therefore suitable for exposure to water or for outdoor use. Zinc coated magnets have a silvery matte or dull patina. Over time this will develop an oxidised protective barrier between the magnetic material and the environment. This helps by reducing corrosion and increasing the magnet's longevity.

Zinc also provides high resistance to abrasion and scratching. Zinc coated Neodymium magnets are used in motors and the Automotive industry. Although we only keep limited numbers of Zinc coated magnets in stock we are happy to assist customers with custom orders.

The zinc coating provides protection of the magnet from corrosion in environments with general humidity. Although they serve well in ambient environments, zinc coated magnets are not well suited to environments where they are wet for extended periods. There are a number of different coating options available. We advise customers to consider the placement of the magnet when selecting a magnet.

We have put together a helpful table which outlines the key characteristics of each coating. You can find this article on our knowledge base page along with many other articles both technical and practical in nature.

Zinc coated magnets have a good resistance to abrasion and scratching. Applications which require regular repositioning of the magnet may utilise these attributes. Zinc coated magnets are suitable for use with adhesives. They can be glued to steel or other materials however specially developed adhesives must be used. Zinc coated Neodymium magnets are used in many types of motors. They are commonly used in the Automotive industry.

Why purchase magnets from AMF

Our team at AMF Magnets strive to pick, pack and dispatch your orders as quickly as possible. We take great pride in not only meeting but exceeding our customer’s expectations. We care about our customer’s experience shopping with us and we welcome any feedback customers would like to share.

Orders are dispatched daily and we work with our delivery partners to cover every corner of Australia. You can simply purchase your zinc coated magnets online and they will be shipped directly to your address. For up to date information about shipping please take a look at our delivery page.

Buy magnets online

Purchasing online offers incredible opportunities however it also has its pitfalls. We know that bricks and mortar stores are appealing for many customers. The ability to physically hold and inspect a product has been a key part of the purchasing process for us all.

Unfortunately there are very limited options in terms of range and quality available from large general suppliers like Bunnings or Officeworks. AMF is proud to be able to offer our customers a generous, no questions asked 30 days returns policy. If the magnets aren’t right for the job, customers can simply send them back (in unused condition) and AMF will refund the purchase price.

FAQ

Why are magnets coated with Zinc?

Zinc coating is applied to magnets, especially Neodymium magnets, to provide a protective barrier against corrosion and wear. While Neodymium is highly magnetic, it is also prone to oxidation. Zinc helps improve durability and extends the magnet’s functional life, especially in indoor or dry environments.

How does a zinc coating affect magnetic strength?

The zinc coating is very thin, just a few microns, so it has minimal effect on the magnetic strength of the magnet. The core material, such as Neodymium, still provides the primary holding power, while zinc protects the magnet without significantly reducing its performance.

Where are zinc-coated magnets commonly used?

Zinc-coated magnets are widely used in industrial assemblies, signage systems, packaging and DIY projects, where moderate moisture resistance is needed but where a more expensive coating like Nickel or Epoxy may not be necessary. Zinc-coated magnets are also popular for temporary fixtures and mounting applications because they offer a strong magnetic hold while remaining cost-effective and resistant to mild corrosion, making them ideal for short-term or indoor use. The Zinc coating provides a protective layer that prevents the magnet from oxidizing, while still allowing easy handling and repositioning without damaging surfaces. This makes zinc-coated magnets especially suitable for mounting signs, displays, or lightweight equipment that may need to be frequently moved or adjusted.

Neodymium Block Magnet – 25.4mm x 9.53mm x 3.2mm | N50M | Zinc Coated | High Temperature ≤100ºC

Code: B-W9.53H3.2L25.4-N50Mzn

Pull Force: 4.89 kg

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Neodymium Disc Magnet – D5mm x 3mm | N48SH | Zinc Coated | High Temperature ≤150°C

Code: D-D5H3-N48SH

Pull Force: 0.743 kg

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 10

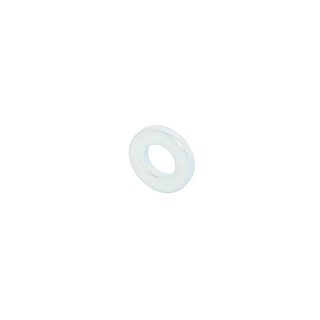

Neodymium Ring Magnet – 19.05mm (OD) x 9.525mm (ID) x 3.175mm (H) | N38 | Zinc Coating

Code: 88968

Pull Force: 3.40 kg

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1