Magnets on a vertical surface

There are a remarkable number of variables at play when it comes to choosing the right magnet. One such variable is the orientation of the metal surface you are adhering magnets to.

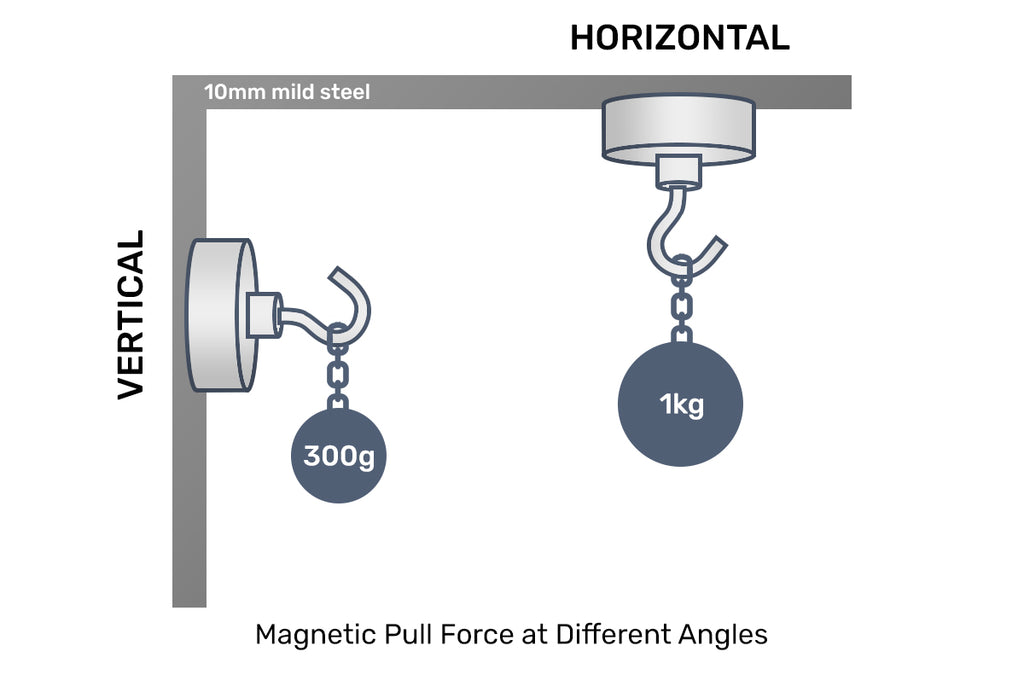

The Pull Force listed for each magnet is based on lifting or bonding against 10mm thick steel in a horizontal position. Magnets on a vertical surface (of 10mm thick steel) are generally able to hold around only 30% of the listed pull force due to the effects of gravity and the lack of traction between the steel surface and the smooth or shiny surface of the magnet.

An example of this 'rule' is a magnet that has been tested to a pull force of 1kg (testing is conducted with 10mm thick steel lifted/holding horizontally). When placed on a vertical surface the pull force is diminished to approximately 300grams.

Fridges and metal lockers are normally constructed with 1mm or 2mm thick steel, which is significantly thinner than the 10mm steel the magnets are tested against and the magnetic field is not able to achieve full saturation of the steel and therefore its 'full' holding capacity.

Also, any gap created by a material (such as paper) between the magnet and the metal surface it is magnetically adhered to will also slightly diminish the holding strength of the magnet.

We do our best to assist customers with finding the best magnets for their application however it often requires some trial and error to select the correct magnet for your project. All the circumstances and environments need to be considered to ensure the right magnetic product is selected.