Magnetic Lifter 1000kg I 3.5x Safety Factor

Product code: 89133

Prices are GST Incl.

Request a Quote for Bulk OrdersAustralia's Leading Supplier

Shipping Worldwide*

30 Day Returns

Same Day Dispatch*

Lifting Magnets Product Description:

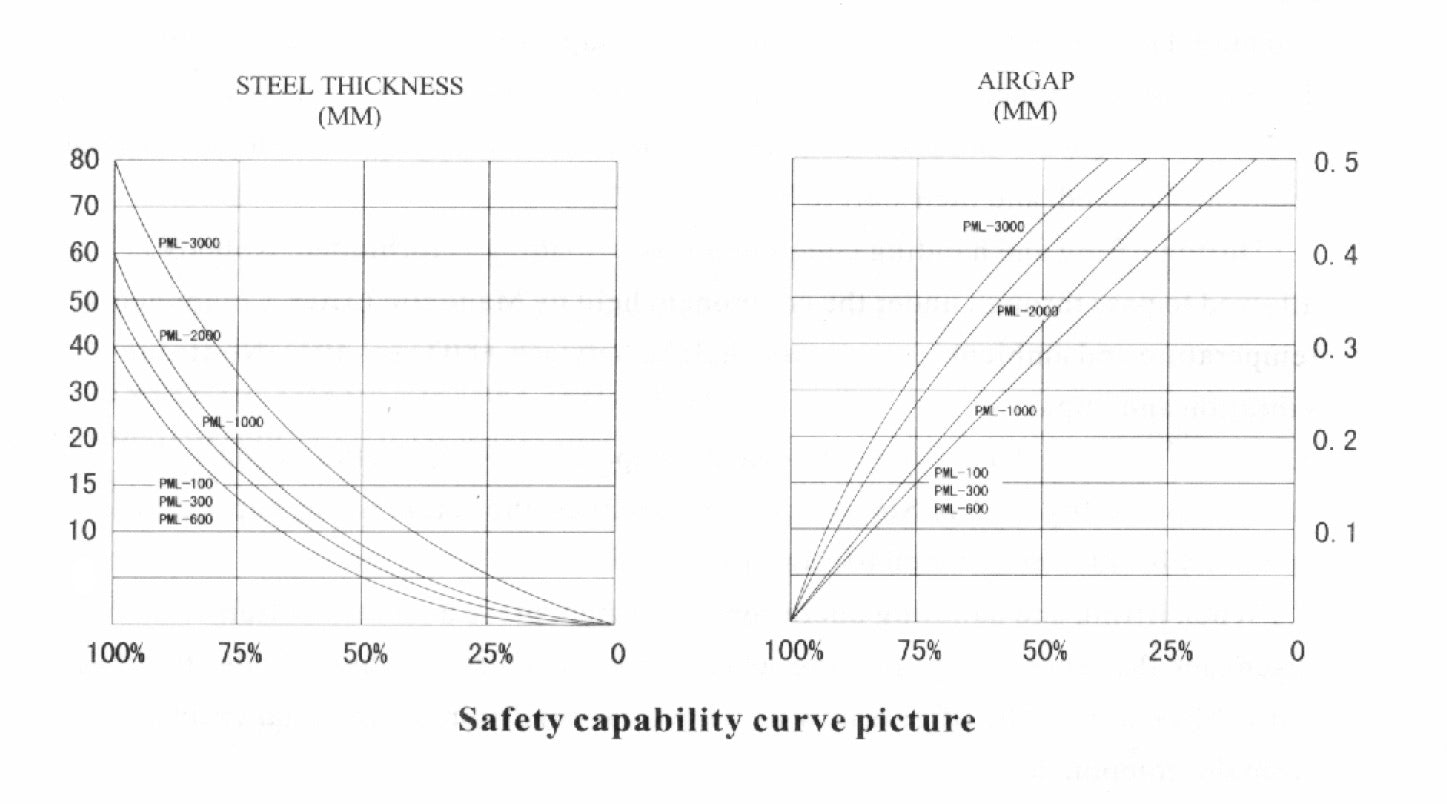

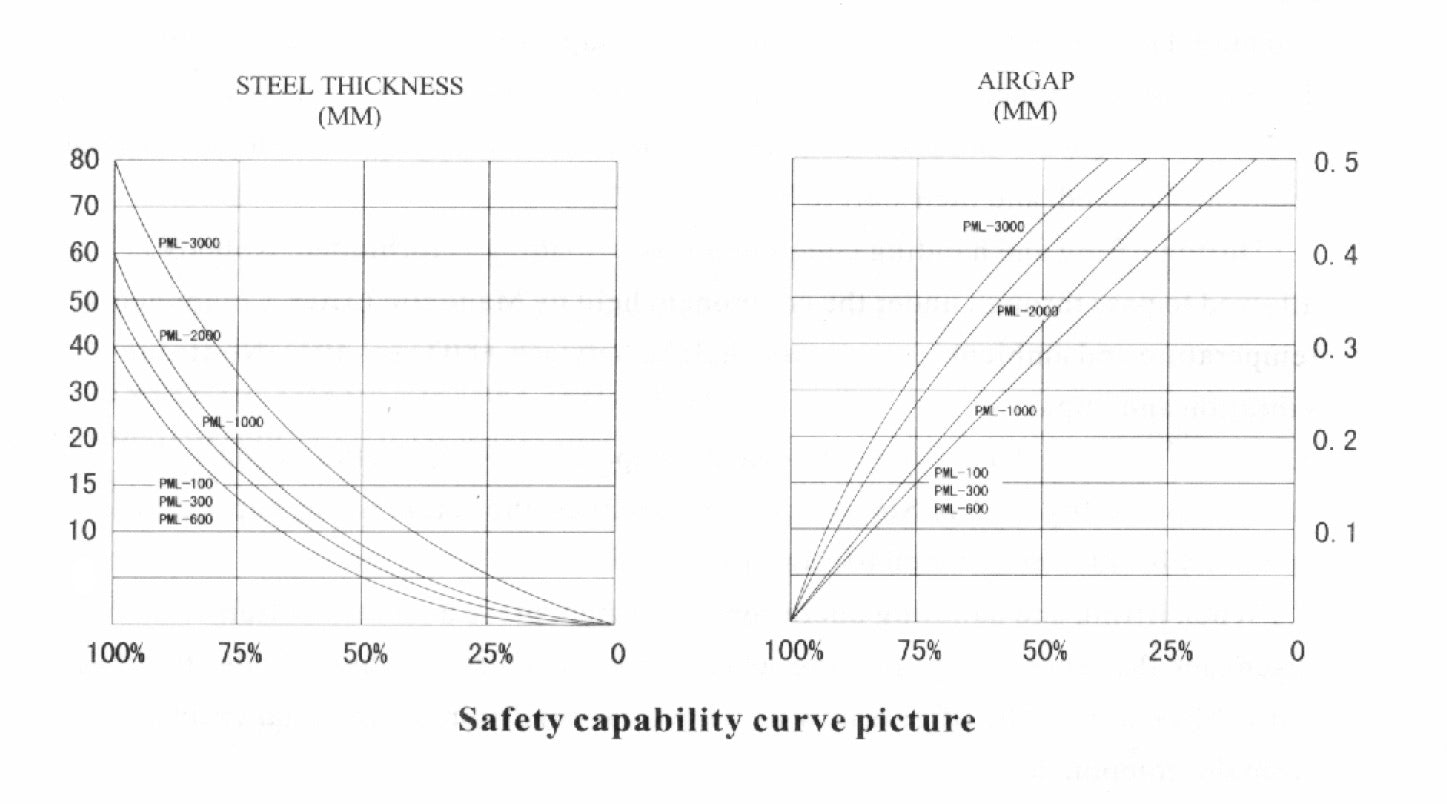

This 1000kg Lifting Magnet has a width of 176mm, a length of 258mm, a height of 163mm, and a 285mm lifter handle. It is identified by the AMF Magnets part number 89133. Important: this magnetic lifter is rated at 1000kg against a minimum of 40mm steel. AMF Magnetics' ranges of high strength magnetic lifters are produced with super strong Neodymium magnets, with your safety in mind. Operation is by way of turning the manual handle once on the operating surface. Magnetic Lifters are a versatile, cost effective and convenient way of loading, unloading and moving steel plates, blocks or cylinders in a safe manner.

All AMF Magnetic Lifters are compliant with Australian Standard AS 4991-2004 which requires a tear-off force of at least 3 times rated capacity for permanent lifting magnets and at least 2 times rated capacity for battery-powered lifting magnets.

AMF's range of magnetic lifters are all permanent magnetic lifters, therefore they do not require a battery or power source to operate.

Any magnetic lifters that do not meet at least a 3:1 Safety Factor, does not comply with the Australian Standard for the legal requirements of safe operation within Australia.

Magnetic Lifters Operation Safety Instructions and Maintenance Manual can be found here.

Uses for our Lifting Magnets:

Whether they be chain or rope slung block and tackle assemblies, truck mounted single jointed hydraulic cranes or fixed, purpose-built, electric powered, heavy lift, steel cabled winches in factories and workshops, all rigging engages magnetic lifters to move steel fabrications around. Once the magnetic lifter has locked onto the products steel surface by virtue of strong magnetic cling or magnetic suction and is committed to the load by the devices locking lever, a rigging hook or clasp is attached to the shackle on top of the magnetic lifter for secure and safe passage of materials.

People everywhere love steel. It’s cheap, strong, easy to maintain and lasts forever (almost). But it is heavy. Where timber and masonry was once used, the switch to steel means handling methods have had to change. Steel products have to be dragged, lifted, carried and released in a very controlled manner. Magnetic lifters engage steel products with powerful magnetic cling, brute force suction, confirming the grab with a locking lever. This same lever applied in reverse, releases magnetic force to effect a controlled release once the object is in position.

Magnetic lifters allow a single person operator to safely lock and unload very heavy loads from a safe distance. Locking on to the top of items to be moved removes the risk of crush injuries inherent in encircling a load with a sling or chain.

Ideal for lifting in factories, docks, warehouses, and transportation or engineering workshops, AMF Magnetics Magnetic Lifters are light, ingeniously constructed for ease of application and have a 3.5 : 1 safety built into each unit. Another key benefit of the Magnetic Lifters is that they are fitted with the strongest magnetic materials available, Rare Earth Neodymium magnets, which will never weaken, providing durable and consistent operation.

| AMF100 | AMF300 | AMF600 | AMF1000 | AMF2000 | AMF3000 | AMF6000 |

No FAQ available

Lifting Magnets Product Description:

This 1000kg Lifting Magnet has a width of 176mm, a length of 258mm, a height of 163mm, and a 285mm lifter handle. It is identified by the AMF Magnets part number 89133. Important: this magnetic lifter is rated at 1000kg against a minimum of 40mm steel. AMF Magnetics' ranges of high strength magnetic lifters are produced with super strong Neodymium magnets, with your safety in mind. Operation is by way of turning the manual handle once on the operating surface. Magnetic Lifters are a versatile, cost effective and convenient way of loading, unloading and moving steel plates, blocks or cylinders in a safe manner.

All AMF Magnetic Lifters are compliant with Australian Standard AS 4991-2004 which requires a tear-off force of at least 3 times rated capacity for permanent lifting magnets and at least 2 times rated capacity for battery-powered lifting magnets.

AMF's range of magnetic lifters are all permanent magnetic lifters, therefore they do not require a battery or power source to operate.

Any magnetic lifters that do not meet at least a 3:1 Safety Factor, does not comply with the Australian Standard for the legal requirements of safe operation within Australia.

Magnetic Lifters Operation Safety Instructions and Maintenance Manual can be found here.

Uses for our Lifting Magnets:

Whether they be chain or rope slung block and tackle assemblies, truck mounted single jointed hydraulic cranes or fixed, purpose-built, electric powered, heavy lift, steel cabled winches in factories and workshops, all rigging engages magnetic lifters to move steel fabrications around. Once the magnetic lifter has locked onto the products steel surface by virtue of strong magnetic cling or magnetic suction and is committed to the load by the devices locking lever, a rigging hook or clasp is attached to the shackle on top of the magnetic lifter for secure and safe passage of materials.

People everywhere love steel. It’s cheap, strong, easy to maintain and lasts forever (almost). But it is heavy. Where timber and masonry was once used, the switch to steel means handling methods have had to change. Steel products have to be dragged, lifted, carried and released in a very controlled manner. Magnetic lifters engage steel products with powerful magnetic cling, brute force suction, confirming the grab with a locking lever. This same lever applied in reverse, releases magnetic force to effect a controlled release once the object is in position.

Magnetic lifters allow a single person operator to safely lock and unload very heavy loads from a safe distance. Locking on to the top of items to be moved removes the risk of crush injuries inherent in encircling a load with a sling or chain.

Ideal for lifting in factories, docks, warehouses, and transportation or engineering workshops, AMF Magnetics Magnetic Lifters are light, ingeniously constructed for ease of application and have a 3.5 : 1 safety built into each unit. Another key benefit of the Magnetic Lifters is that they are fitted with the strongest magnetic materials available, Rare Earth Neodymium magnets, which will never weaken, providing durable and consistent operation.

| AMF100 | AMF300 | AMF600 | AMF1000 | AMF2000 | AMF3000 | AMF6000 |

No FAQ available