Magnets

BEST MAGNETS EVER

AMF Magnetics

Hi Lorraine,

What an absolutely fantastic review to receive! We're absolutely thrilled to hear you think these are the BEST MAGNETS EVER - that's exactly the kind of enthusiastic feedback that makes our day!

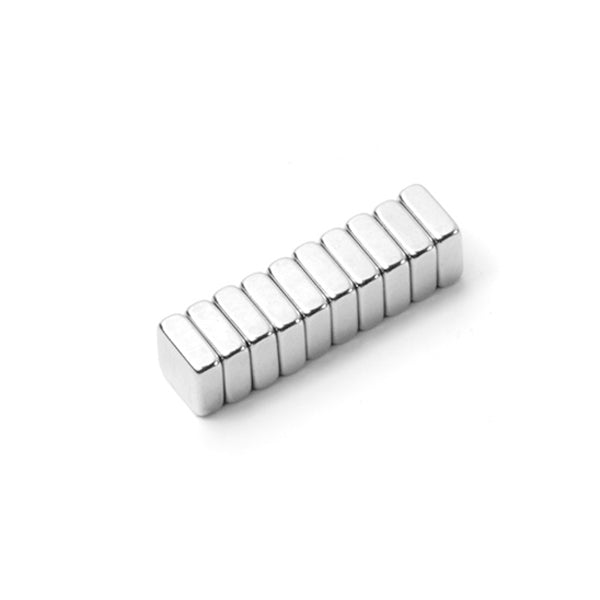

These compact 6.35mm x 6.35mm x 2.5mm neodymium block magnets really do pack incredible magnetic strength into such a small, precise size. The square profile and slim 2.5mm thickness make them incredibly versatile for so many different applications where you need powerful holding force in a compact form.

Thank you so much for the amazing 5-star review and for choosing AMF Magnetics!