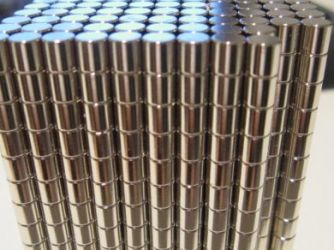

Magnetic Product Description:

This popular rare earth cylinder has a diameter of 4mm and a height of 4mm. It is an N48 grade rare earth magnet. It has a magnetic flux reading of 6318 Gauss and a pull force of 0.576kg. It is identified by the AMF magnet part number C-D4H4-N48.

Uses for our rare earth cylinder magnets:

Small magnets that are cylindrical in shape are suited to placement inside circular drill holes or round recesses in plastic. They can then act as an attachment point for metal or make a closure mechanism with a magnet with the opposite pole exposed. The magnet can be glued in position or held in place with a thin covering which the magnetic field is able to penetrate.

Tiny magnetic closures and magnetic joins of this type are increasing in popularity with hobbyists, model makers and fashion accessory designers. The magnetic field is virtually invisible and far less conspicuous than traditional fastening methods that use clips, buttons or pins. Also referred to as rod magnets, these small magnets have a strong pull force relative to other types of permanent magnets of the same size.

Rare earth magnets were first developed in the 1980s and have since become the magnet of choice for most commercial operations where heat is not a factor. For high temperature applications it is more appropriate to use Ferrite, Alnico or Samarium Cobalt.