Neodymium Disc Magnet - 20mm x 10mm | N45H | High Temperature ≤120ºC

Product code: D-D20H10-N45SH

Prices are GST Incl.

Request a Quote for Bulk OrdersAustralia's Leading Supplier

Shipping Worldwide*

30 Day Returns

Same Day Dispatch*

Magnetic Product Description:

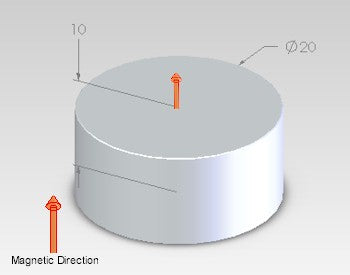

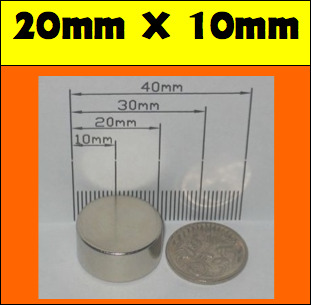

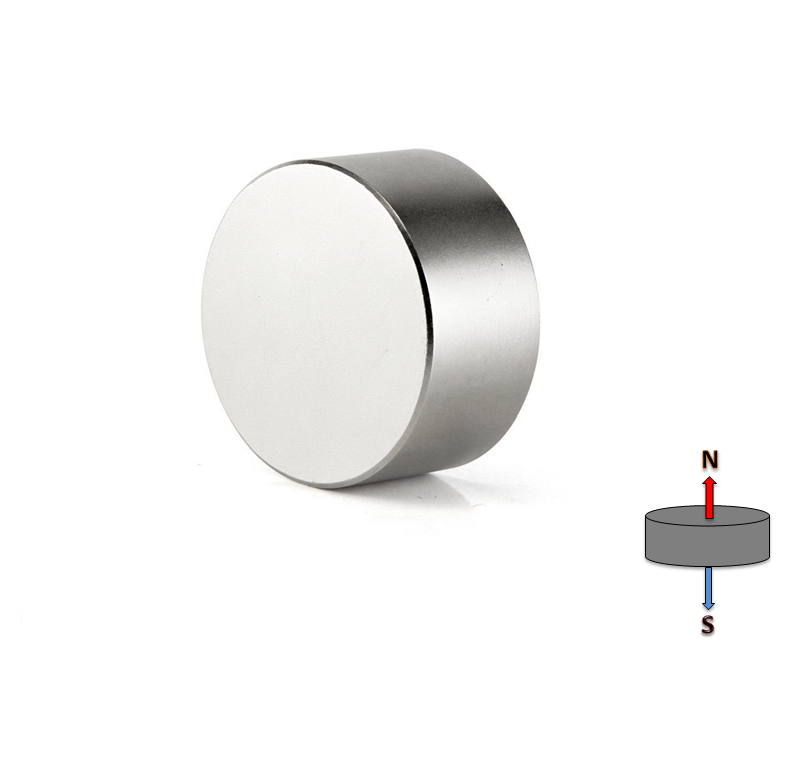

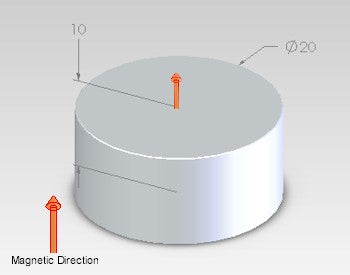

This Rare Earth Disc Magnet has a diameter of 20mm and a height of 10mm. It has a magnetic flux reading of 4844 Gauss and a pull force of 13.09 kilograms. This magnet has a N45H grade, which enables it to withstand environments less than or equal to 120ºC. It is identified by the AMF Magnetics part number D-D20H10-N45SH.

Uses for our Rare Earth Disc Magnets:

When the going gets tough, the tough get going. For a 20mm x 10mm Neodymium Disc Magnet allied to tools and equipment in the mining industry to blast, drill, cut, crush, load and process rock, that is saying something. The phrase ‘rock hardness’ is commonly used in the industry and helps explain why tools and equipment associated with mining are of a different grade and scale compared to other tools and equipment made for other industries.

The task of excavating, transporting and processing of ore (rocks) requires a dedicated team of workers and purpose built tools and machines of a scale and cost the world has never seen before. It is hard to imagine what else, apart from mining, these rock breaking pieces of equipment could be used for.

For such punishing work, steel fabricated technologies are a necessity in the mining industry. These 20mm x 10mm neodymium disc magnets, embedded in the mining tools and equipment, can be found all over the mine site. From helping out the rotary blast hole drill bits readying another section of rock for dynamiting, to the dozer mounted long wall boring attachment and the three storey driverless dump trucks, magnets mix with the toughest of machines, for the heaviest work, in the most demanding of all conditions. Like they say. When the going gets tough, the tough get going.

No FAQ available

Magnetic Product Description:

This Rare Earth Disc Magnet has a diameter of 20mm and a height of 10mm. It has a magnetic flux reading of 4844 Gauss and a pull force of 13.09 kilograms. This magnet has a N45H grade, which enables it to withstand environments less than or equal to 120ºC. It is identified by the AMF Magnetics part number D-D20H10-N45SH.

Uses for our Rare Earth Disc Magnets:

When the going gets tough, the tough get going. For a 20mm x 10mm Neodymium Disc Magnet allied to tools and equipment in the mining industry to blast, drill, cut, crush, load and process rock, that is saying something. The phrase ‘rock hardness’ is commonly used in the industry and helps explain why tools and equipment associated with mining are of a different grade and scale compared to other tools and equipment made for other industries.

The task of excavating, transporting and processing of ore (rocks) requires a dedicated team of workers and purpose built tools and machines of a scale and cost the world has never seen before. It is hard to imagine what else, apart from mining, these rock breaking pieces of equipment could be used for.

For such punishing work, steel fabricated technologies are a necessity in the mining industry. These 20mm x 10mm neodymium disc magnets, embedded in the mining tools and equipment, can be found all over the mine site. From helping out the rotary blast hole drill bits readying another section of rock for dynamiting, to the dozer mounted long wall boring attachment and the three storey driverless dump trucks, magnets mix with the toughest of machines, for the heaviest work, in the most demanding of all conditions. Like they say. When the going gets tough, the tough get going.

No FAQ available