Magnets

Super strong - extremely well packaged +++

| Quality |

Rated 5 out of 5

|

|---|---|

| Ease of Use |

Rated 5 out of 5

|

| Value |

Rated 5 out of 5

|

| Strength |

Rated 5 out of 5

|

Product code: 22007

Prices are GST Incl.

Request a Quote for Bulk OrdersAustralia's Leading Supplier

Shipping Worldwide*

30 Day Returns

Same Day Dispatch*

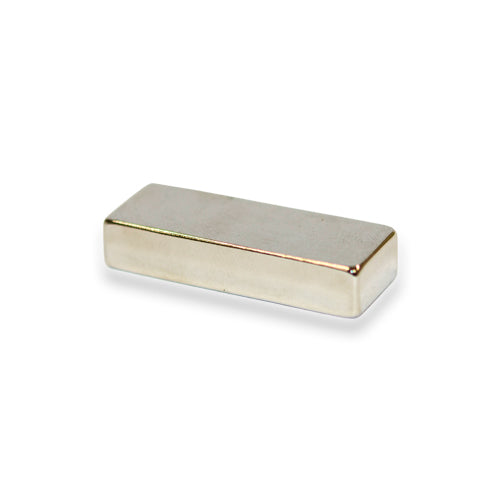

This rectangular block magnet measures 40mm in length, 15mm in width, and 8mm in height. It features a pull force of 19.98 kg and a magnetic flux density of 2767, coated with durable Nickel. It is catalogued under AMF Part Number 22007.

This Neodymium Block magnet offers a moderate strength level within the AMF product lineup. Measuring 40mm x 15mm x 8mm, it delivers a notable pull force of 19.98kg. Its high N52 magnetic grade ensures superior power compared to similarly sized Rare Earth magnets with lower grades.

Neodymium block magnets like these are commonly employed in industrial settings, often serving as virtual ‘torque limiters.’ In this role, the magnets act as safety devices that yield under excessive load or stress, helping to protect machinery from damage and reduce the risk of injury.

These magnets are also suitable for various applications that demand a moderate pull force, including knife holders, water purification, secure holding, and a range of engineering and industrial tasks.

Yes, you can. We suggest the maximum air gap is 2mm only (thickness of the wood between the magnet and knife). Your project requires a trial-and-error approach depending on the very light weight of the objects. It depends on the thickness of timber, the weight of the item you wish to attach, quality of steel to name a few variables. Also note that vertically placed magnets/knives will lose 70% of their pull force. If you are attaching different tools, some heavier than others, you may have to increase the pull force (size, diameter/thickness) of the magnets. Here's our video tutorial using these magnets: https://www.youtube.com/watch?v=JwO6Fu4SYTQ

This rectangular block magnet measures 40mm in length, 15mm in width, and 8mm in height. It features a pull force of 19.98 kg and a magnetic flux density of 2767, coated with durable Nickel. It is catalogued under AMF Part Number 22007.

This Neodymium Block magnet offers a moderate strength level within the AMF product lineup. Measuring 40mm x 15mm x 8mm, it delivers a notable pull force of 19.98kg. Its high N52 magnetic grade ensures superior power compared to similarly sized Rare Earth magnets with lower grades.

Neodymium block magnets like these are commonly employed in industrial settings, often serving as virtual ‘torque limiters.’ In this role, the magnets act as safety devices that yield under excessive load or stress, helping to protect machinery from damage and reduce the risk of injury.

These magnets are also suitable for various applications that demand a moderate pull force, including knife holders, water purification, secure holding, and a range of engineering and industrial tasks.

Yes, you can. We suggest the maximum air gap is 2mm only (thickness of the wood between the magnet and knife). Your project requires a trial-and-error approach depending on the very light weight of the objects. It depends on the thickness of timber, the weight of the item you wish to attach, quality of steel to name a few variables. Also note that vertically placed magnets/knives will lose 70% of their pull force. If you are attaching different tools, some heavier than others, you may have to increase the pull force (size, diameter/thickness) of the magnets. Here's our video tutorial using these magnets: https://www.youtube.com/watch?v=JwO6Fu4SYTQ

The Pull Force listed for each magnet is based on lifting 10mm thick steel from a horizontal surface. Magnets on a vertical surface (of 10mm thick steel) are generally able to hold around only 30% of the pull force listed in the product description. This is due to the effects of gravity and the lack of friction between the surface and the shiny magnet. Read More