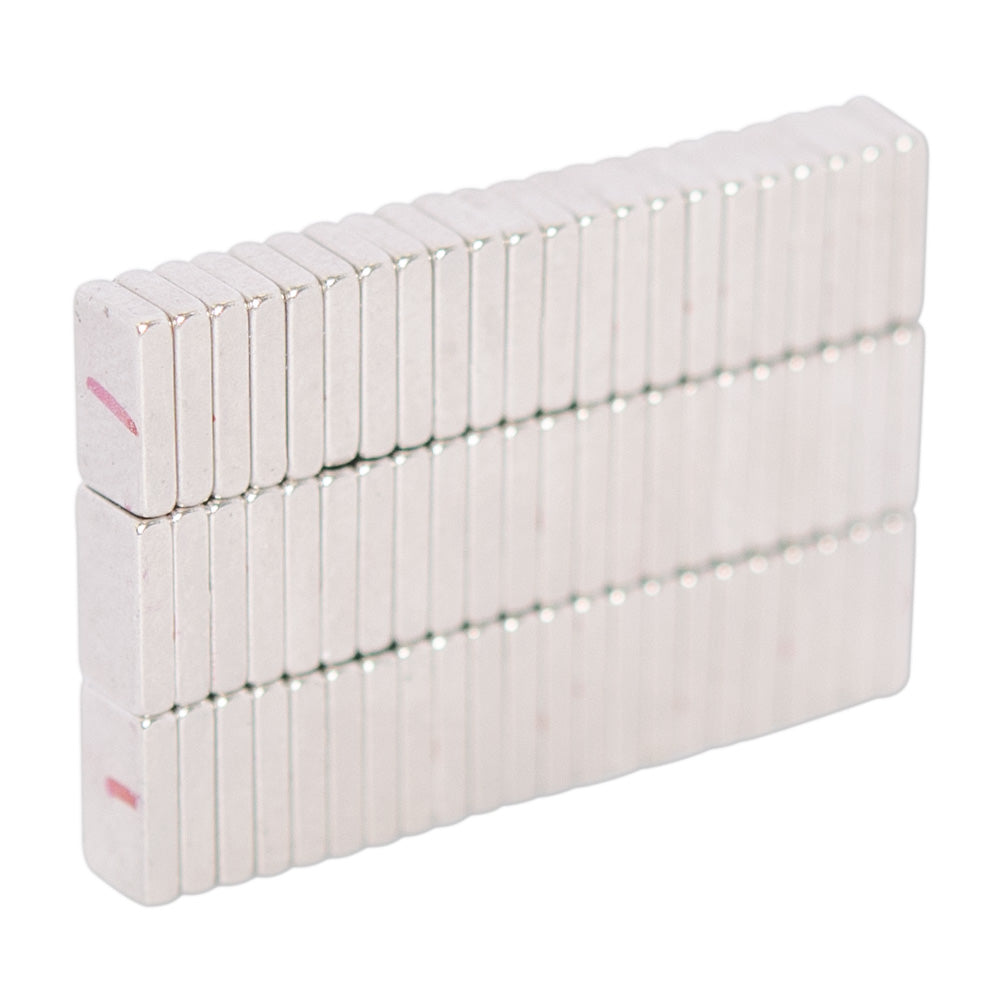

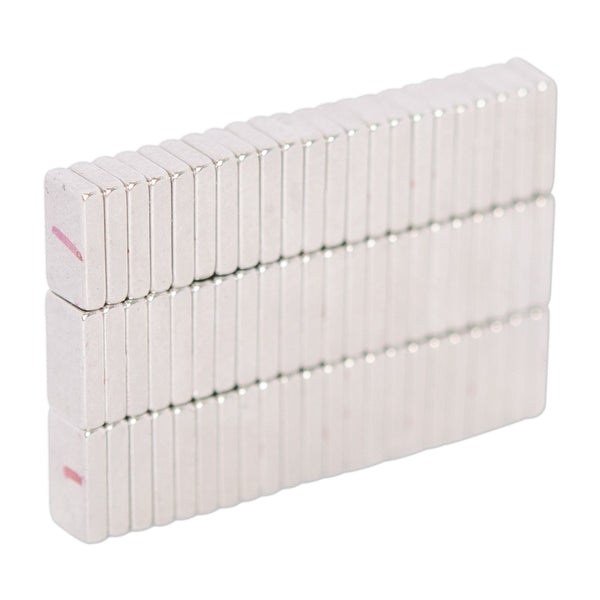

Neodymium Block Magnet - 5mm x 3mm x 1mm N50

Product code: B-W3H1L5-N50

Prices are GST Incl.

Request a Quote for Bulk OrdersAustralia's Leading Supplier

Shipping Worldwide*

30 Day Returns

Same Day Dispatch*

Magnetic Product Description:

These Neodymium Block Magnets have a length of 5mm, a width of 3mm and a height of 1mm. It has a magnetic flux reading of 6912 Gauss and a pull force of 0.311 kilos. This product is identified by the AMF magnet part number B-W3H1L5-N50.

Uses for our rare earth block magnets:

Neodymium rectangular magnets or block magnets are super strong magnets that have the dual benefit of smaller mass and greater magnetic strength than other types of permanent magnet. Permanent magnets operate without any requirement for electricity or any other type of external power source. Neodymium magnets provide constant and reliable magnetic hold or pressure under normal conditions. The nickel coating that protects the strong Neodymium material prevents corrosive forces from damaging the magnetic.

Small Rare Earth block magnets have a shape that is suited to secure placement inside electric devices, particularly sophisticated sensors. Many modern-day electronic products rely on the power of small Neodymium block magnets to operate. Block magnets can be fitted onto an alloy or plastic right-angled framework to make component parts attach magnetically. Small Neodymium magnets are used to amplify and electrically transmit sound waves in microphones, speakers and headphone equipment.

No FAQ available

Magnetic Product Description:

These Neodymium Block Magnets have a length of 5mm, a width of 3mm and a height of 1mm. It has a magnetic flux reading of 6912 Gauss and a pull force of 0.311 kilos. This product is identified by the AMF magnet part number B-W3H1L5-N50.

Uses for our rare earth block magnets:

Neodymium rectangular magnets or block magnets are super strong magnets that have the dual benefit of smaller mass and greater magnetic strength than other types of permanent magnet. Permanent magnets operate without any requirement for electricity or any other type of external power source. Neodymium magnets provide constant and reliable magnetic hold or pressure under normal conditions. The nickel coating that protects the strong Neodymium material prevents corrosive forces from damaging the magnetic.

Small Rare Earth block magnets have a shape that is suited to secure placement inside electric devices, particularly sophisticated sensors. Many modern-day electronic products rely on the power of small Neodymium block magnets to operate. Block magnets can be fitted onto an alloy or plastic right-angled framework to make component parts attach magnetically. Small Neodymium magnets are used to amplify and electrically transmit sound waves in microphones, speakers and headphone equipment.

No FAQ available