Rare Earth Magnets Production Flow Diagram

AMF has been in business since the 1980s and we have developed relationships with a number of high calibre factories. We work closely with our suppliers and we have a detailed understanding of their manufacturing processes. As with any long standing business we have from time to time had concerns arise regarding product quality or performance. However our depth of knowledge allows us to work with the factories to identify and address any areas of concern.

Our website has been put together with an eye to providing our customers with the information and knowledge to assist them in finding the right magnets for their application. We endeavour to provide transparency in all aspects of our business. Our team continues to grow our FAQ and Knowledge Base to incorporate as many of the common questions as possible.

In this flow chart you can see the simplified process of Neodymium magnet production. Rare Earth magnets have been available to the market since the 1980s and have revolutionised technology across a broad spectrum of industries. Their ability to provide a strong magnetic field from a relatively small magnet has led to advances in many electronic products.

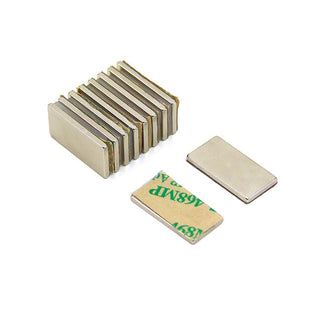

The coating process is one of the final steps in the production of a Neodymium magnet. However it is also one of the most critical in terms of creating a magnet that is able to perform reliably. Neodymium is a porous material that is highly reactive and would corrode quickly if not protected by an external plating that coats the outside of the magnet. Even normal ambient humidity would lead to the magnet’s corrosion and subsequent performance decline. There are a number of coatings available, for more details on their corresponding attributes please refer to the Magnet Coatings article on our FAQ. If you would like to review the products available with a particular coating please select from the Coating filter on the top of the web page.

You can view our full range of Neodymium magnets on our website and you are welcome to contact our team if you have any questions.