Magnetic Product Description:

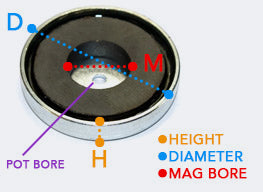

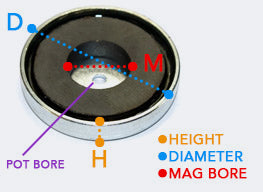

This ferrite pot magnet has a diameter of 25mm and a height of 8mm. It has a countersunk magnet bore and a 5.3mm pot bore. This ferrite magnet is identified by the AMF Magnetics part number 89017.

Uses for our Ferrite Pot Magnets:

Our ferrite pot magnets have a mild steel casing over a ferrite ring magnet with a round central hole for fixing a bolt, rivet or screw, for attaching to non-magnetic surfaces. With no moving parts this ferrite pot magnet requires no maintenance beyond ensuring the magnet is clean before use.

Businesses requiring display casings for the promotion or communication of products and services engage companies to produce and install these assemblies. Due to the changing nature or stock and trading conditions and the requirement for regular cleaning or changing faulty light bulbs housings and casings, our ferrite pot magnets make adjustments to the contents quick and easy to perform.

These magnets are used to lock individual components like frames, backboards, and glass and plastic shields together. Components fastened with magnets release at an intuitive pull force and dissemble for the placement of updated signs or new prices, snapping back together for display as if for the first time.

These ferrite pot magnets, contain a central void able to take a screw, bolt or rivet for fixture to nonmagnetic surfaces and can be used to attach the total display assembly to any surface inside or outside the place of business.

Threaded pot magnets are able to accept a hook or eyelet for another fastening option. Signs and display casings need to be placed or attached to all kinds of surfaces and materials in different kinds of workplaces and workspaces. Magnetic engagement allows easy assembly and disassembly minimising material penalty, increasing the durability and longevity of these important signs.

Magnetic engagement for the display housings themselves to walls or bulkheads increases the options when installing these casings. Keeping the need to pierce architectural surfaces in newly visited workplaces to a minimum avoids potential problems with the unknown. Unknowns like water pipes, electrical cables and loose material. Magnetic engagement epitomises the light touch philosophy that is secure and permanent yet easily removable, with the minimum material penetration to minimise hazards of installing fixtures in places of business visited for the first and last time.

| ModelNo. |

D |

d1 |

Magnet Bore

|

Pot Bore (mm) |

H |

Pull force |

Weight (g) |

| 89016 |

40 |

|

8.6mm |

M5 thread |

8 |

7 kg |

0.0950 |

| 89017 |

25 |

|

C/sunk |

5.3 |

8 |

|

0.0170 |

| 89018 |

32 |

|

C/sunk |

5.8 |

7 |

|

0.0280 |

| 89019 |

36 |

|

9mm hole |

4.8 |

7 |

|

0.0370 |

| 89020 |

55 |

|

22mm |

4.6 |

11 |

12 kg |

0.0600 |

| 89030 |

88 |

|

32mm |

13.6 |

18 |

30 kg |

0.0700 |

| 89031 |

90 |

18 |

C/sunk |

10 |

12 |

30 kg |

0.0700 |