Neodymium Block Magnet - 30.2mm x 22mm x 19.1mm with Cut-Out Channel 7.3mm | N38

Product code: 93488

Prices are GST Incl.

Volume pricing available on requestAustralia's Leading Supplier

Shipping Worldwide*

30 Day Returns

Same Day Dispatch*

Neodymium Block Magnet - 30.2mm x 22mm x 19.1mm with Cut-Out Channel 7.3mm | N38

Magnetic Product Description:

This rectangular block magnet has a length of 30.2mm, a width of 22mm, and a height (or thickness) of 19.1mm. It has a cut-out channel which is 7.3mm in diameter. This magnet has a Gauss reading of 11,300 and a pull force of 21.31 kilograms. This product is identified by the AMF Magnetics part number 93488.

Uses for our Rare Earth Block Magnet with Channel:

This Neodymium block magnet is a custom design that AMF created for a major civil engineering company.

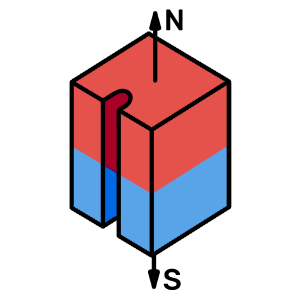

Unlike the majority of block magnets, this item has an unusual direction of magnetisation. The North and South poles are located at each end of the cut-out channel as depicted in the adjacent diagram. The magnetic field travels through the 30.2mm length dimension.

Magnets like this are designed for a particular application and are usually needed to solve a problematic design issue or to improve general efficiency in a processing system. The cut-out channel can be useful for either securing the magnet in a particular position or allowing limited lateral movement of the magnet when positioned correctly. In other applications, the magnet may be used as a detection sensor to activate important processes or to automatically trigger failsafe systems when a production problem arises.

This item has an incredible 11000 gaus magnetic output that generates 21.31kg pull force against thick steel.

No FAQ available

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.